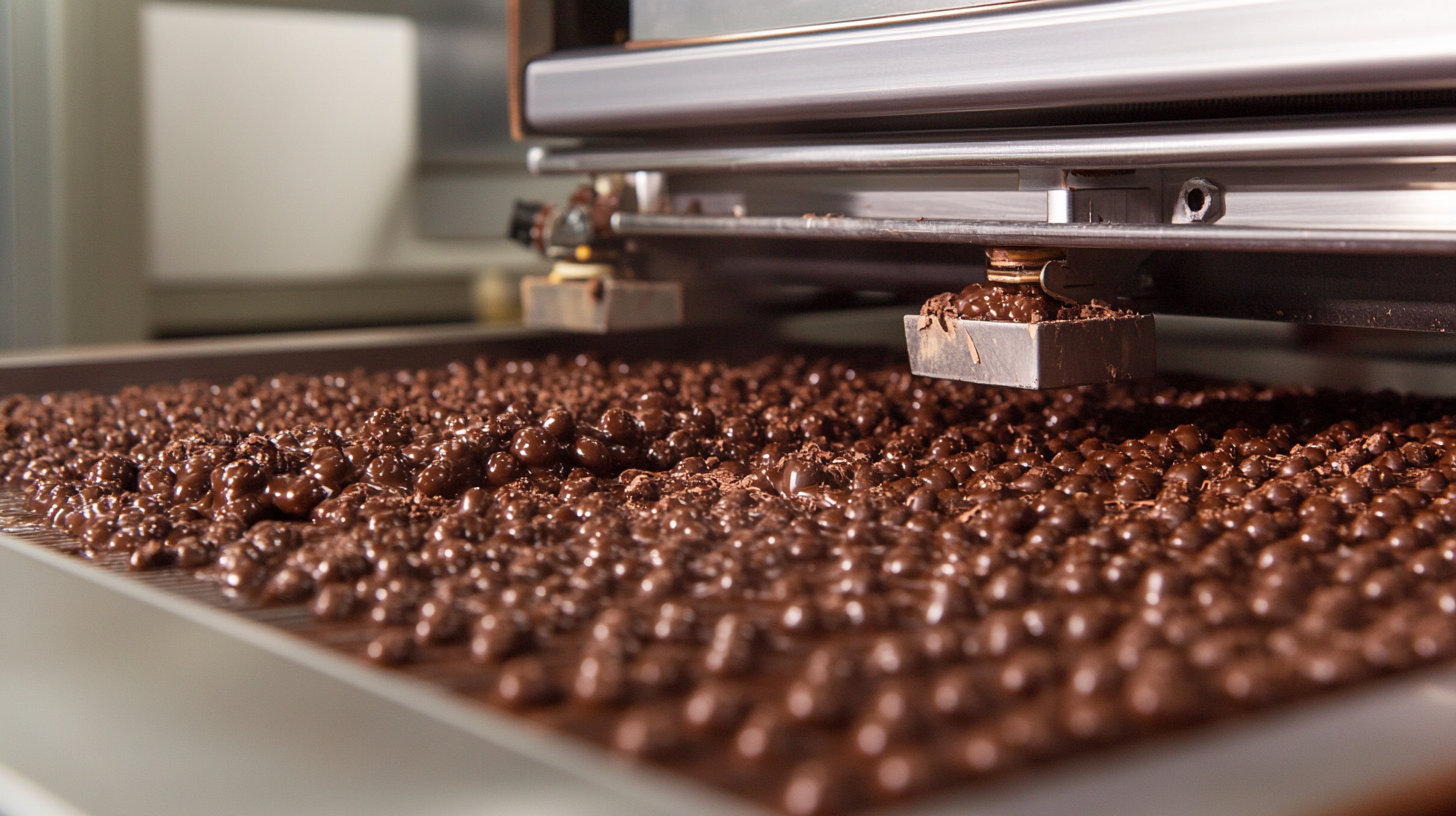

In the world of chocolate production, achieving the perfect texture and flavor is paramount, and this is where "Temperatrici per il cioccolato" come into play. These specialized machines are designed to regulate the temperature of chocolate, ensuring it solidifies correctly while retaining its exquisite sheen and snap.

Understanding the different types of temperatrici available, along with their unique features and suitable applications, is essential for chocolatiers aiming to enhance their craft. From small artisanal setups to large-scale production facilities, selecting the right tempering machine can significantly impact the quality of the final product.

In this blog, we will explore the advantages of various temperatrici per il cioccolato, discuss how to choose the best one for your specific needs, and unlock the key to excellence in chocolate making. Join us as we delve into the intricacies of chocolate tempering and discover how the right equipment can elevate your confections to new heights.

The global chocolate market is experiencing a remarkable surge, with the premium chocolate segment projected to grow significantly in the coming years. According to a recent report by Grand View Research, the premium chocolate market is expected to reach USD 98.3 billion by 2026, growing at a CAGR of 4.6% from 2019. This rising demand is pushing chocolate manufacturers to seek superior tempering equipment that ensures quality and consistency, ultimately meeting consumer expectations for high-end chocolate products.

The global chocolate market is experiencing a remarkable surge, with the premium chocolate segment projected to grow significantly in the coming years. According to a recent report by Grand View Research, the premium chocolate market is expected to reach USD 98.3 billion by 2026, growing at a CAGR of 4.6% from 2019. This rising demand is pushing chocolate manufacturers to seek superior tempering equipment that ensures quality and consistency, ultimately meeting consumer expectations for high-end chocolate products.

As consumer preferences shift towards artisanal and premium offerings, the importance of state-of-the-art temperatrici cannot be overstated. These tempering machines not only enhance the texture and sheen of chocolate but also improve the overall flavor experience. A report from Market Research Future indicates that advanced tempering machinery equipped with precise temperature controls can reduce production time by up to 30%, making it an ideal choice for manufacturers aiming to scale their operations while maintaining product excellence. Therefore, investing in the best temperatrici is essential for producers looking to thrive in the competitive premium chocolate market.

When it comes to chocolate production, the quality of your temperatrici can make all the difference. High-quality temperatrici are designed to efficiently control temperature, ensuring that the chocolate achieves the perfect viscosity and shine. Look for machines that offer precise temperature regulation and consistent performance to streamline your production process.

One key feature to consider is the ability to handle large quantities while maintaining uniform heating. Models that come equipped with advanced heating and cooling elements are ideal, as they can quickly adapt to the changes in chocolate consistency during the tempering process. Additionally, easy-to-clean surfaces and built-in safety features are essential for a seamless operation.

**Tip:** Always calibrate your temperatrici for optimal performance. Regular maintenance checks will help you identify any inconsistencies in temperature, allowing you to prevent chocolate spoilage. Furthermore, investing in a model that offers programmable settings can save you time and ensure that your chocolate achieves the desired texture every time.

The chocolate industry is poised for significant growth as we approach 2025, with global market estimates indicating an impressive expansion. According to recent studies, the chocolate market size is projected to soar to USD 219.1 billion by 2033, at a compound annual growth rate (CAGR) of 2.76%. This upward trend is driven by various factors, including increasing consumer preferences for premium and artisanal chocolate products, as well as rising demand for sustainably sourced cocoa.

In the United States, the chocolate market is also set to experience notable growth, with a CAGR of 2.51% projected from 2025 to 2033. As health-conscious consumers seek out products with better ingredients and lower sugar content, manufacturers are responding by innovating and diversifying their product offerings. This shift not only reflects broader lifestyle changes but also emphasizes the importance of quality production processes, such as utilizing advanced temperatrici for achieving optimal chocolate texture and flavor. The synergy of market trends and technological advancements in chocolate production is likely to play a crucial role in shaping the industry's future landscape.

When it comes to chocolate production, the choice of temperatrici can significantly impact the quality and consistency of the end product. Investing in advanced temperatrici may require a higher upfront cost, but the long-term benefits often outweigh the initial expenditure. These machines offer precise temperature controls and automated processes, reducing human error and ensuring that chocolate maintains the ideal crystalline structure. The resulting chocolate not only has a superior texture but also boasts a higher gloss finish and a longer shelf life, making it more appealing to consumers.

Comparing the cost to the benefits reveals that the initial investment in high-quality temperatrici can lead to substantial savings over time. With decreased production waste, lower labor costs due to automation, and the potential for higher sales from premium chocolate products, manufacturers can see a quick return on their investment. Moreover, as consumer demands for quality increase, having state-of-the-art equipment ensures chocolate producers stand out in a competitive market. Ultimately, the right temperatrici can transform the production process, providing chocolatiers with the tools they need to create exceptional products that meet consumer expectations.

The world of chocolate production is undergoing a remarkable transformation thanks to technological innovations in tempering equipment. Traditional methods of chocolate tempering, which relied heavily on manual techniques, have been replaced by advanced temperatrici that streamline the process. These state-of-the-art machines ensure that chocolate reaches the precise temperature needed for optimal crystallization, resulting in a glossy finish and a satisfying snap. With features like automated stirring, real-time temperature monitoring, and user-friendly interfaces, modern temperatrici are designed to enhance both efficiency and consistency in chocolate production.

Moreover, the integration of smart technology into tempering equipment signifies a leap toward the future. Machines equipped with IoT capabilities allow chocolatiers to remotely monitor and control the tempering process, minimizing the risk of human error and optimizing productivity. Innovations such as rapid temperature modulation and energy-efficient designs not only improve the quality of the final product but also reduce waste and energy consumption. As the chocolate industry continues to evolve, embracing these technological advancements is essential for manufacturers aiming to produce high-quality chocolate while adhering to sustainable practices.

Utilizziamo i cookie per migliorare l'esperienza utente. Per maggiori informazioni, consulta la nostra Cookie Policy.